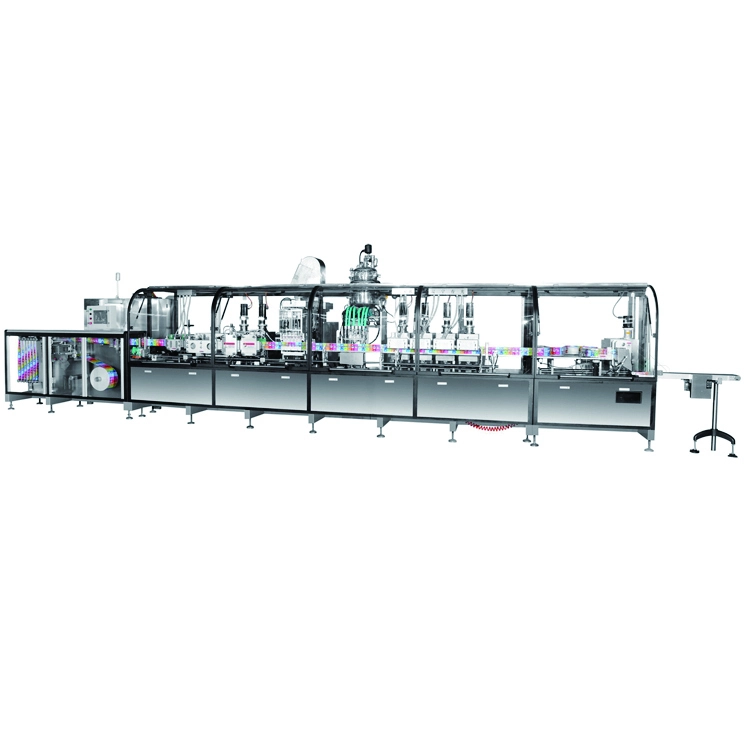

Automatic kids snack cheese stick forming filling sealing machine

The cheese stick packaging machine has the following characteristics:

1. Adopting advanced Siemens PLC control system and operation panel, the operation is simple and easy to learn.

2. The compact appearance design takes up little space and does not occupy too much production space, saving the company's rental costs.

3. We use high-precision sensors and controllers to ensure that the size, weight, and sealing of each packaging bag are accurate and error free.

4. Automated packaging involves a series of actions such as loading, measuring, cutting, bagging, and sealing, all in one step, reducing employee labor intensity and minimizing human errors, thereby improving production efficiency and quality.

5. Equipped with automatic detection of missing materials, coding, opening bags, bagging and other functions, making maintenance more convenient;

Automatic kids snack cheese stick forming filling sealing machine

UN-40N stick cheese filling machine is a liquid and semi-viscous body measured in plastic container packaging units. Using a thermoforming film, the film is folded in half by a film folding device and then formed. If necessary, the equipment can produce flat-bottom bottle type (self-standing bottle type) and special-shaped bottle. UB-40N stick cheese filling machine can complete the process from forming, filling, sealing until the finished product is punched and transported to the outside of the machine.

1. Purpose

This machine is suitable for unit-dose packaging, suitable for packaging medicines, beverages, dairy products, health products, condiments, food, cosmetics and other fluid and semi-fluid products. Its unique structure, complete functions, stable performance, reliable quality, and international advanced level of similar products. It is currently the highest level in this field in China.

2. Features

It has a wide range of applications, such as food, medicine, cosmetics, skin care and health care products, and chemical products. The mold is flexible, easy to replace, intelligent system control, modular design, process innovation, simple operation, minimum loss of packaging materials, and high utilization rate 95%-99%, saving packaging costs. Diversified forms of packaging, not restricted by shape, can produce upright, special-shaped and independent bottle shapes.

Parameters of stick cheese filling machine:

Machine dimensions (standard) | 10500x1285x1850(mm) |

Total Weight | 5000Kg |

Input voltage | Three-phase 380V |

Power | 45kw |

Power cable cross-sectional area | >6mm⊃2; |

frequency | 50Hz |

Maximum withstand current | 50A |

Compressed air consumption | When 0.6 Mpa, 120L/min |

Working temperature | 10~22°C |

Cooling water inlet and outlet size | φ16mm(Quick plug) |

Air source inlet size | φ12mm(Quick plug) |

Cooling water consumption | Temperature 14-18℃, pressure 0.15-0.2Mpa, 280L/H in closed loop |

Packaging Materials | PVC/PE, PET/PE, PVDC and other composite sheets Specifications (0.3~0.4)*245max (mm) (or according to mold specifications) The maximum diameter of the film roll is Φ600mm The inner diameter of the film roll tube core is Φ76mm |

Filling count per plate | ≤15 pcs/plate (depending on filling measurement) |

Productivity | ≤35 times forming/min |

Dosage range | 1-120ml/piece |

Filling accuracy | ≤2% |

Double-sided molding depth | ≤25mm |

Single-sided molding depth | ≤12.5mm |

Features of stick cheese filling machine

1. The production line is simple and safe, which can reduce the production cost of the product.

2. Modular design, simple structure, short design cycle and quick product update.

3. Reasonable structure, reliable quality, stable operation and long service life.

4. It is widely applicable to packaging materials, PVC/PE, PET/PE, PVC/PVDC/PE and other materials can be molded.

5. The utilization rate of packaging materials is high, usually reaching more than 95%, and some

SUPM is a national high-tech enterprise integrating R&D, production, sales and related services of pharmaceuticals, food, cosmetics industries.