Granule and Tablet Coating Machine

Application:

Grain and tablet coating machine is kind of equipment integrating elegance, high efficiency, energy-saving, safety, easy to clean, which is applied for coating traditional Chinese and Western tablets and pills (including micro-pills, small pills, water-bindered pills, drip pills and granulated pills) with sugar, organic film, water soluble film, slow and controlled release film in the fields of pharmacy, food and biology etc.

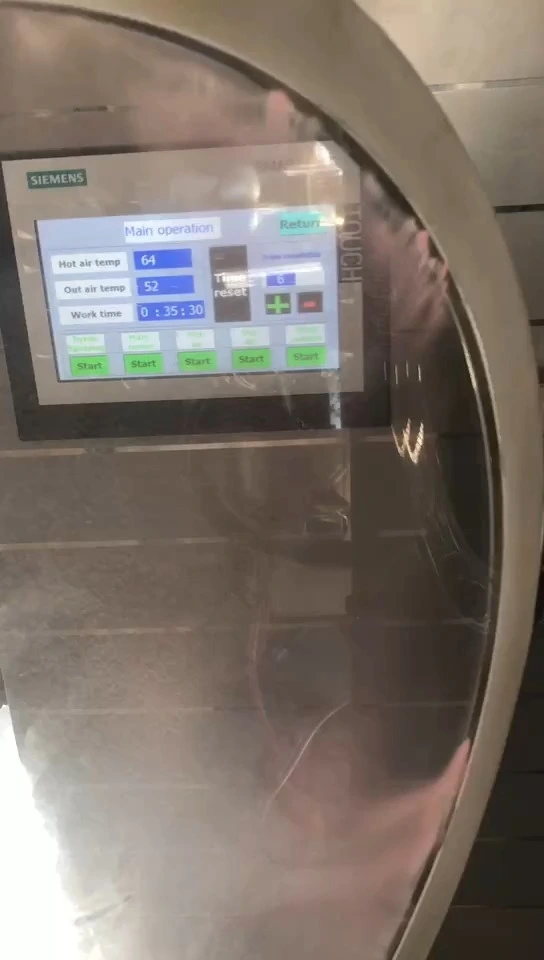

Grain and tablet coating machine is equipped with the programmable PLC (machine and person interface), with which its operation process and process parameters such as negative pressure and temperature can be automatically controlled. It is easy to operate, with reasonable and advanced process during run of the machine.

| Technical\ Type | 400E | 150(D)E | 80(D)E | 40(D)E | 10D | |

| Load Capacity (kg) | 400 | 150 | 80 | 40 | 10 | |

| Revolutions(R/Min) | 2.0-12 | 2.0-14 | 2.0-16 | 2.0-18 | 3.0-19 | |

| Machine dimensions kw | 3 | 2.2 | 1.5 | 1.1 | 0.55 | |

| Machine dimensions (L*W*H) mm | 2050*1670 *2360 | 1730*1320 *2030 | 1370*1050 *1700 | 1100*850 *1470 | 900*700 *1400 | |

| Diameter of Coating drum mm | 1500 | 1200 | 930 | 780 | 500 | |

| Power of Air Exhaust Cabinet Motor kw | 7.5 | 5.5 | 3 | 2.2 | 0.75 | |

| Air exhaust flow m3/h | 10000 | 7419 | 5268 | 3517 | 1285 | |

| Power of Hot Air Cabinet Motor kw | 2.2 | 1.5 | 1.1 | 0.75 | 0.37 | |

| Hot air flow m3/h | 3600 | 2356 | 1685 | 1285 | 816 | |

| Weight of Main Machine kg | 1200 | 850 | 600 | 500 | 200 | |

| Overall Dimensions of Air Exhaust Cabinet mm | 1000*900*1650 | 900*800 *1500 | 750*600 *1130 | |||

| 1050*1050 *2000 | 950*950 *1950 | 900*820 *1850 | 820*720 *1750 | 750*600 *1130 | ||

| Air Consumption | Pressure MPa | >0.39 | ||||

| m3/min | 1.5 | 0.5 | 0.35 | 0.2 | 0.2 | |

Product Introduction

Performance and Characteristics:

1. The drum of the main machine has a closed poreless structure and is equipped with a flow-guiding sheet. Tablets can make easy and smooth rotation without fragment and chipped edge in the drum due to mirror polishing of its wall and flow-guiding sheet, which greatly improves the yield.

2. During air intake, three times filtration involving primary filtration, medium filtration and high filtration, can reach 100, 000 level purification. During air exhaust, dust abatement can reach 99% by adopting a bag-type dust extractor. Equipped with a vibration damper, the machine is in normal run with noise lower than 75dB, which conforms to environmental protection requirements.

3. A specially designed air source exchange system features exchange of hot air an cold air depending on the technological requirements, so to say, the fan blade can be regarded as air inlet or air outlet. An eye pitch explosion-proof lamp is equipped in the drum so as to clearly view all material in run for the convenience of accurate control of technological change.

4. A cleaning system I equipped at the bottom of the drum, with automatic computer-controlled drain after cleaning.

5. The specially designed imported spray gun features easy to operate and control relevant technological requirements, uniform density and particle size, uniform atomization and large spray area, practical to adjust flow, angle and sector, economization on dressing, free leakage and blockage. The gun can be in operation unless its head keeps in the range of 0.29Mpa to 0.39Mpa. It has been favourably reviewed from users at home and abroad.

6. Features PLC automatic control of such process parameters as negative pressure, air flow and temperature etc, automatic run of various process flow in sequence, instead of manual operation.

7. Equipped with a data storage and printing system, by which process parameter and process flow of each batch of production can be accurately recorded with a printer as requested from users.

Product Display

SUPM is a national high-tech enterprise integrating R&D, production, sales and related services of pharmaceuticals, food, cosmetics industries.