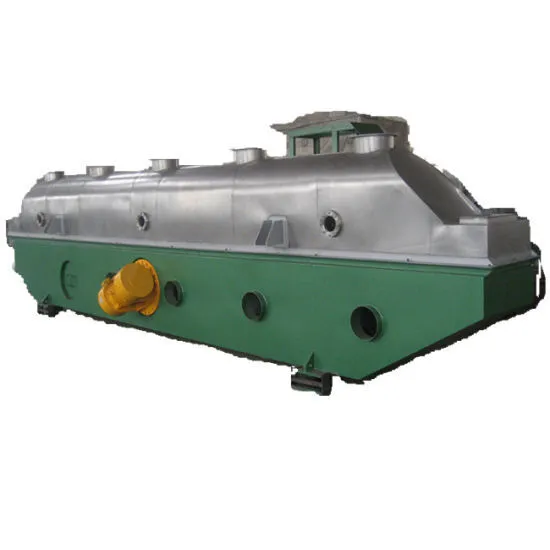

Horzitonal Fluidized Dryer Drying Equipment

Horzitonal Fluidized Dryer Drying Equipment

Description

Fluidized dryer is also called fluid bed. Through operation and improvement over 30 years, it has play an active part in the fields of pharmaceutical, chemical, foodstuff, gain and so on industries. It consists of air filter, fluid bed, cyclone separator, dust collector, high-speed centrifugal fan, control cabinet and so on. Because of the difference of property from raw material, it is necessary to equip dust remover in accordance with practical needs. It may select cyclone separator and dust collector both or one of them. In general, cyclone separator can be selected if the raw material is larger and the dust collector may be selected if the raw material is light. Moreover, there is pneumatic feeding device for your selection. There are two kinds of operation for this machine, continuous and intermittent type.

Principle

The clean and hot air enters into fluid bed through distributor of valve plate. The wet material is fed from the feeder forms the fluid state by hot air. Because of the wide contact between hot air and raw materials, the time of drying is short. If use continuous type, the material enters from the front of bed, fluidized in bed for several minutes, and float another side of bed. The machine' works in negative pressure.

Applications

Drying process of medicines, chemical raw material, foodstuff, grain processing, feed and so on. For example, raw medicine, tablet, Chinese medicine, foodstuff of health protection, drinks, feed, resin, citric acid and other powders. The suitable diameter of raw material is normally 0.1-0.6mm. The most applicable diameter of raw material will be 0.5-3mm.

Notes: The drying capacity is measured based on the primary moisture of crystal of plum is 20% and its final moisture is 5% and the temperature of air inlet is 130 º C. The drying capacity of other raw materials will be based on the practical drying condition. When choose models, please note that: Model A should be matched with cyclone separator and Model B with inside bag dust collector and Model C with cyclone separator and bag dust collector.

Explanation to installation

All equipment should be horizontal and fixed with foundation screw on the ground. All parts should be sealed well.

The fan may be installed outdoor or in the special noise free room. The plan can be adjusted slightly in accordance with the real conditions.

| model | drying capacity kg/h | power of fan | air pressure pa | air amount m3/h | Tem. of inlet airºC | Max consumption J | Form of feeding |

| XF10 | 10-15 | 7.5 | 5.5×103 | 1500 | 60-200 | 2.0×108 | 1. shape valve 2. pneumatic conveying |

| XF20 | 20-25 | 11 | 5.8×103 | 2000 | 60-200 | 2.6×108 | |

| XF30 | 30-40 | 15 | 7.1×103 | 3850 | 60-200 | 5.2×108 | |

| XF50 | 50-80 | 30 | 8.5×103 | 7000 | 60-200 | 1.04×109 |

1.Nomally shipping steps:

2.Our packing and shipping:

Pre-Sales Service:

* Inquiry and consulting support.

*Quickly reaction.

*Factory inspection available anytime.

After-Sales Service:

*Prompt technical support

*Engineers available to service machinery overseas

*Installation &commissioning,good training for customers.

Q1.What's your delivery method?

A1:We commonly use sea transportation, using container to deliver the goods through Shanghai Port.

Q2.What products can you provide?

A2:Our main product includes powder mixers,granulating equipments,drying equipments,capsule fillers,blister packing machines,tablet/capsule counting filling line,ampoule/vial/oral liquid filling line includes ultrasonic washing machine,sterilization oven,filling capping machine,labeling machine.

Q3. What's the payment terms?

A3:We will confirm the payment with you when quoting, like FCA, CIF or others.T/T is the main payment.

Q4.How do you ensure your product quality?

A4:We conduct inspections in every production procedure, and for finished products, we will take 100% inspection depend on international standards according to customer's requirements.

Q5:Does the machine power voltage meet buyers' factory power source?

A5: We can do it as your request.

Q6: Is it difficult to install the machine ?

A6: For standard small machines, the machines will be packed with no take apart, it comes to you to be a complete machine; you just need to connect power and compressed air to machine, then begin to operate the machine.

For large size machines, we will take the machine apart, on condition that we do our best to keep the machine easy to assembly.

You will get videos and instructions about installation of machine from us.

SUPM is a national high-tech enterprise integrating R&D, production, sales and related services of pharmaceuticals, food, cosmetics industries.