Powder Four-Side Sealing & Multi-Line Packing Machine

Usage:

Suitable for packing powder material in the pharmacy(medicine), food, daily chemical and other industries, automatic packing into sachet with Measurement requirement, Such as flour, coffee powder, starch, milk powder, all kinds of drugs, chemical powder, and much more.

Features:

1. Advanced performance, high power, low noise, compact structure, Operate steadily, easy to maintain, and has a long life span.

2. Adopt five shaft servo motor in step driver, man-machine interface touch adjustment, controlled by PLC, it is precise in automatic in step positioning.

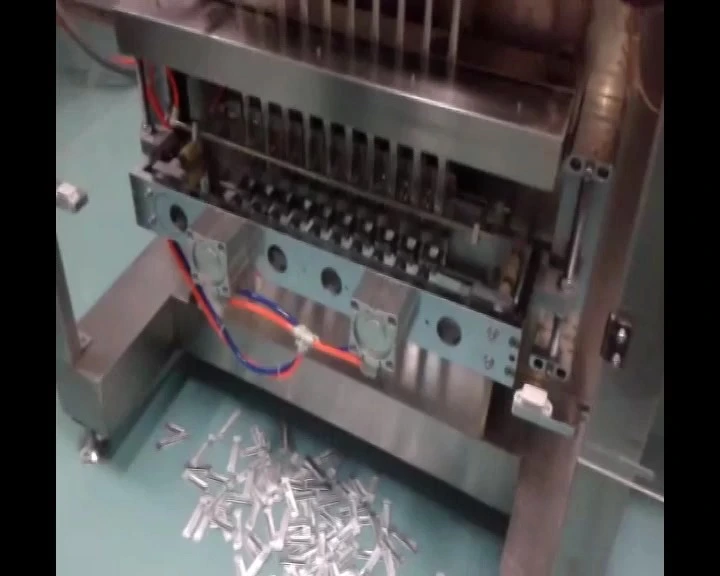

3. A high degree of automatic. Machine can finish packing at one time from longitudinal sealing, longitudinal cutting, transverse sealing, filling, embossing, notch cutting, cutting Dotted line, transverse cutting to outputting finished sachets.

4. High precision whole rolling type heat sealing roller are adopted as sealing mould. 4-side sealing, multi-line sachets form. Because liquid material will easily leak in sealing side, an extra smooth unstriated sealing roller is setup to ensure sealing sides compact and tightly. With high packing speed, smooth bag shape, delicate and beautiful, packaging with high efficiency.

5. Fast and convenient to adjust, it can step-less adjust pouch length without changing the mould. And can adjust the functions as longitudinal sealing, transverse sealing, filling, embossing, Dotted line cutting and transverse cutting through man-machine interface.

6. Accurate in measurement, According to liquid material, specifically designed of centrifugal liquid pump for filling, measuring control adopt high precise electro-magnetic valve, each valve match with voltage regulator, each line's dosage can be adjusted easily and accurately.

7. A PLC is used for automatic control, Each actuating mechanism adopt servo motor to driver, it is precise in automatic in step positioning, reliable performance, convenient to operate, and fully automatic.

8. Photoelectric tracking system is adopted to ensure correct printing and with automatic counting function.

9. Adaptability of the package film. The sealing temperature of machine is with automatic control, and with high control accuracy (± 1C ° ). Suitable for most complex film packing film in home and abroad, as PET/AL/PE, PET/PE, NY/AL/PE, NY/PE and so on.

10. Extra function set up, for example, sachet cutting can choose dotted line knife, flat cutting knife or abnormal shape knife. And can choose different kinds of alarm requirements and so on.

Usage:

Suitable for packing powder material in the pharmacy(medicine), food, daily chemical and other industries, automatic packing into sachet with Measurement requirement, Such as flour, coffee powder, starch, milk powder, all kinds of drugs, chemical powder, and much more.

Features:

1. Advanced performance, high power, low noise, compact structure, Operate steadily, easy to maintain, and has a long life span.

2. Adopt five shaft servo motor in step driver, man-machine interface touch adjustment, controlled by PLC, it is precise in automatic in step positioning.

3. A high degree of automatic. Machine can finish packing at one time from longitudinal sealing, longitudinal cutting, transverse sealing, filling, embossing, notch cutting, cutting Dotted line, transverse cutting to outputting finished sachets.

4. High precision whole rolling type heat sealing roller are adopted as sealing mould. 4-side sealing, multi-line sachets form. Because liquid material will easily leak in sealing side, an extra smooth unstriated sealing roller is setup to ensure sealing sides compact and tightly. With high packing speed, smooth bag shape, delicate and beautiful, packaging with high efficiency.

5. Fast and convenient to adjust, it can step-less adjust pouch length without changing the mould. And can adjust the functions as longitudinal sealing, transverse sealing, filling, embossing, Dotted line cutting and transverse cutting through man-machine interface.

6. Accurate in measurement, According to liquid material, specifically designed of centrifugal liquid pump for filling, measuring control adopt high precise electro-magnetic valve, each valve match with voltage regulator, each line's dosage can be adjusted easily and accurately.

7. A PLC is used for automatic control, Each actuating mechanism adopt servo motor to driver, it is precise in automatic in step positioning, reliable performance, convenient to operate, and fully automatic.

8. Photoelectric tracking system is adopted to ensure correct printing and with automatic counting function.

9. Adaptability of the package film. The sealing temperature of machine is with automatic control, and with high control accuracy (± 1C ° ). Suitable for most complex film packing film in home and abroad, as PET/AL/PE, PET/PE, NY/AL/PE, NY/PE and so on.

10. Extra function set up, for example, sachet cutting can choose dotted line knife, flat cutting knife or abnormal shape knife. And can choose different kinds of alarm requirements and so on.

| Bag length | 50-150mm(L) (pouch length can change) |

| Bag width | 60-105mm(W) |

| Max packing speed | 20-40times/min depend on pouch size and material |

| Measuring range | 1-80ml |

| Sealing fashion | 4 side sealing |

| Applicable film | PET/AL/PE PET/PE NY/AL/PE NY/PE |

| Max width of film roll | 900mm |

| Max film roll diameter | Φ300mm |

| Film roll core diameter | Φ75 mm |

| Power voltage | 380V/ 50HZ( do as customer's request) |

| Power | 12KW |

| Package size | (L)1650mm×(W)1500mm×(H)2200mm |

| G.W | 1500KG |

1.Nomally shipping steps:

2.Our packing and shipping:

Pre-Sales Service:

* Inquiry and consulting support.

*Quickly reaction.

*Factory inspection available anytime.

After-Sales Service:

*Prompt technical support

*Engineers available to service machinery overseas

*Installation &commissioning,good training for customers.

Q1.What's your delivery method?

A1:We commonly use sea transportation, using container to deliver the goods through Shanghai Port.

Q2.What products can you provide?

A2:Our main product includes powder mixers,granulating equipments,drying equipments,capsule fillers,blister packing machines,tablet/capsule counting filling line,ampoule/vial/oral liquid filling line includes ultrasonic washing machine,sterilization oven,filling capping machine,labeling machine.

Q3. What's the payment terms?

A3:We will confirm the payment with you when quoting, like FCA, CIF or others.T/T is the main payment.

Q4.How do you ensure your product quality?

A4:We conduct inspections in every production procedure, and for finished products, we will take 100% inspection depend on international standards according to customer's requirements.

Q5:Does the machine power voltage meet buyers' factory power source?

A5: We can do it as your request.

Q6: Is it difficult to install the machine ?

A6: For standard small machines, the machines will be packed with no take apart, it comes to you to be a complete machine; you just need to connect power and compressed air to machine, then begin to operate the machine.

For large size machines, we will take the machine apart, on condition that we do our best to keep the machine easy to assembly.

You will get videos and instructions about installation of machine from us.

Versatile

The Powder Four-Side Sealing & Multi-Line Packing Machine offers a versatile packaging solution that can accommodate a wide range of powdered products, making it suitable for use in various industries.

Efficient

With its multi-line packing capability, this machine allows for high-speed production and increased productivity, providing a cost-effective and time-saving packaging solution for large-scale manufacturing operations.

Have A Questions?

The Four-Side Sealing & Multi-Line Packing Machine is a versatile and efficient packaging solution for a wide range of powders. With its four-side sealing capability, this machine ensures airtight and secure packaging, keeping the product fresh and safe from external contaminants. Its multi-line packing feature allows for faster and more efficient processing, increasing productivity and reducing operational costs. This Oil Sealing Packing Machine is suitable for various industries, offering a reliable and convenient packaging solution for powdered products.

Product advantages

The Four-Side Sealing & Multi-Line Packing Machine is designed to provide efficient and precise packaging for a variety of products, including powders and granules. With its advanced four-side sealing technology, this machine ensures airtight and secure packaging, keeping products fresh and prolonging shelf life. Additionally, its multi-line packing feature allows for increased production capacity and faster packaging, making it an ideal solution for businesses looking to streamline their packaging processes.

Sink Como

technical sheet

The Powder Four-Side Sealing & Multi-Line Packing Machine is designed to efficiently package and seal powdered products from multiple lines in a compact and reliable manner. With its four-side sealing capability, it ensures a secure and airtight packaging for a longer shelf life of the products. The machine's multi-line packing feature allows for increased productivity and faster packaging of multiple products simultaneously, making it ideal for businesses looking to boost their output.

Product application

The Powder Four-Side Sealing & Multi-Line Packing Machine is designed for packaging products in a four-side sealing style, ensuring a tight and secure seal. It also has the capability to pack multiple lines at once, boosting efficiency and productivity. This machine is ideal for packaging oil and other powdered products with precision and speed.

FAQs

SUPM is a national high-tech enterprise integrating R&D, production, sales and related services of pharmaceuticals, food, cosmetics industries.