automatic Diagonal Labeling Machine

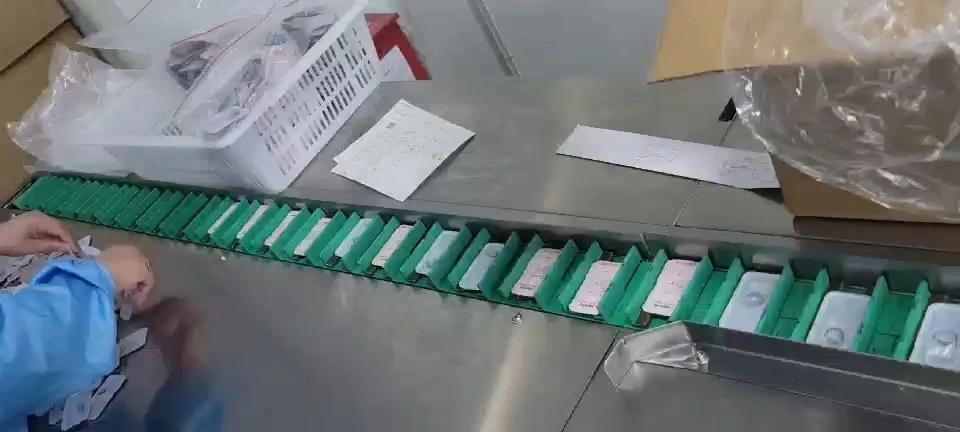

automatic Diagonal Labeling Machine Workflow:

Single row horizontal lying position feeding - sorting - conveying - synchronous top belt clamping -2 labels are respectively attached to the upper/lower positions of both sides (semi upright suspended) - double side surface labeling - labeling both sides towards the top/bottom corners - single row horizontal lying position discharging

The boxes are arranged horizontally, and before labeling, they are separated by a sorting wheel to obtain the required spacing for labeling and smoothing. Then, they are clamped and operated by the main conveyor belt and synchronous top belt. When arriving at the labeling station, trigger the measuring electric eye and trigger the labeling head to apply the label to the end face (side) of the box. Then, under the clamping operation of the top belt and the main conveyor belt, the hanging parts of the two labels are respectively adjusted to the top and bottom of the box through corner adjustment. It can achieve double-sided diagonal sealing and pasting of packaging boxes.

The whole machine is controlled by PLC, with a Chinese interface touch screen operation interface. All electrical control parameters, operating parameters, status, and counting can be set and stored on the touch screen for more than 50 sets of formulas, and formula parameters can be directly called.

When replacing tags of different lengths, there is no need to adjust the position of the tag eye. Simply set or call the corresponding stop position on the touch screen.

Automatic diagonal labeling machine is a device that can stick rolled paper or metal foil labels onto specified packaging containers or products. The back of the label comes with adhesive and is arranged in a regular pattern on a smooth base paper. The peeling mechanism on the labeling machine can automatically peel it off. Labeling can complete various operations such as flat pasting, single-sided or multi-faceted pasting of packaging materials, cylindrical pasting, partial or full coverage cylindrical pasting, concave and corner pasting, etc

There are many types of automatic diagonal labeling machines with different functions, but their basic principles are similar. Automatic labeling machine is a device that uses adhesive to stick paper or metal foil labels onto specified packaging containers.

It can complete various operations such as flat pasting, single-sided or multi-faceted pasting of packaging materials, cylindrical pasting, partial or full coverage cylindrical pasting, concave and corner pasting, etc.

Features

A、 Wide applicability: It can not only achieve single label/corner marking on the side (flat) of square/flat bottles (full bottle state), but also achieve single/double label covering function for circumferential positioning of round bottles

B、 Unique material sorting mechanism ensures reliable and effective material sorting when used in conjunction with the production line

C、 The unique corner labeling mechanism ensures that the corner labels on the three sides of the square bottle are flat and wrinkle free

D、 Can be used independently or in conjunction with production lines

The distance between the top and bottom of the label and the bottom of the backing paper is 2mm

Adhesive label parameters:

Base paper: 62 grams of white Gracin base paper should be selected, which is dense and has good internal strength and transparency, firm and not easily torn. The die-cutting performance is excellent.

Basic weight: 62g/㎡ ± 5% Thickness: 55 μ m ± 5%

Tensile strength: Machine direction: 16kg/25mm Horizontal: 7kg/25mm

Tear resistance: Machine direction: 25g/sheet, horizontal direction: 31g/sheet

Transparency: 52% Label spacing: 3mm ± 0.15mm

The distance between the top and bottom of the label and the bottom of the backing paper is 2mm

2, Technical parameters

SUPM is a national high-tech enterprise integrating R&D, production, sales and related services of pharmaceuticals, food, cosmetics industries.