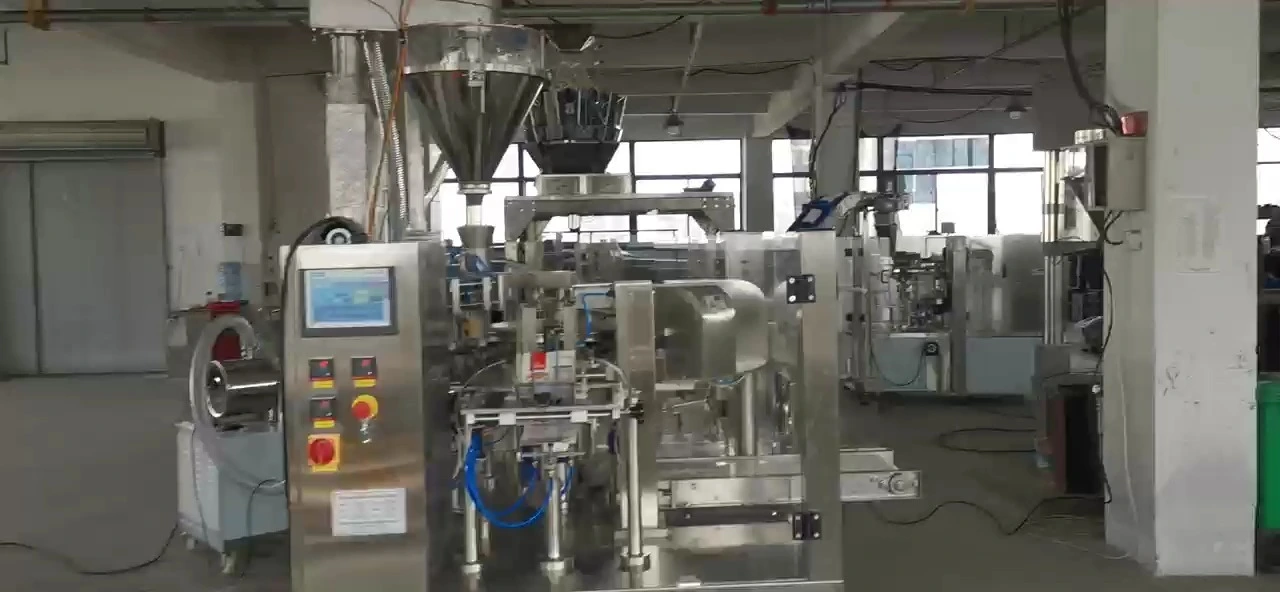

Self standing zipper bag powder packing machine

1. This packaging machine can produce various bag shapes, such as vertical bags.

2. The whole machine is driven and controlled by PLC, servo motor, and touch screen, which maximizes the control accuracy, speed range, reliability, and intelligence of the whole machine, simplifies the mechanical transmission system, significantly reduces mechanical noise and failure rate, and makes the operation and use of the whole machine simple and easy.

3. Equipped with a fault display system, it can quickly identify the cause and location of equipment faults, helping to troubleshoot them in a timely manner.

4. The vertical and horizontal seals adopt high-precision tooth shaped design, making the seal very tight and leak proof.

5. The sealing temperature and action completion time of the packaging film are independently set to achieve the optimal packaging effect of the product.

6. Equipped with inflation and exhaust devices, nitrogen and carbon dioxide inflation devices can be added.

7. Replacing the filling machine head can adapt to various materials.

Main technical parameters:

model | TS8-250C |

Packaging type | Flat bag, three sided seal, four sided seal, self-supporting bag, etc |

Packaging bag material | Composite film, PP, PE, etc. |

Bag size | W:100-250mm L:150-350mm |

Weight range | 10-2000g |

Packaging speed | 20-40 bags per minute (Its speed is determined by the material itself and the weight of the filling) |

Gas consumption | 0.4m3/min |

Packaging accuracy | ≤±1% |

power supply | 4.75KW,AC220V,60Hz |

Machine dimensions | 4300*1650*2450mm |

weight | 2200kg |

Scope of application:

This equipment is composed of a bag packaging machine, a screw scale, and a spiral feeding machine, mainly suitable for automatic measuring and packaging of powder materials.

Main performance characteristics:

1. Easy to operate: using PLC control and human-machine interface operating system, making the operation intuitive and convenient;

2. Easy adjustment: Changing varieties can be completed within about two minutes;

3. Suitable for different types of packaging bags;

4. A comprehensive prevention system ensures high yield and prevents wastage of bags and materials;

5. The packaging of the machine is made of stainless steel material to ensure the hygiene and safety of the materials;

6. The machine adopts a fully automatic detection device to achieve automation of the packaging process, reduce labor intensity for workers, and save labor.

7. Partial use of imported engineering plastics, no need for refueling, reducing material pollution;

8. Adopting oil-free vacuum pump to avoid polluting the production environment.

SUPM is a national high-tech enterprise integrating R&D, production, sales and related services of pharmaceuticals, food, cosmetics industries.