vacuum emulsifier,Vacuum Emulsifying Mixer for Pharmaceutical, Cosmetic, and Chemical

Vacuum Emulsifying Mixer is a vital tool in the production of high-quality products in various industries, ensuring efficiency, consistency, and stability in the manufacturing process.

SUPM is a professional pharmaceutical machinery and packaging machine manufacturer in China! We are specialized in pharma machinery and packaging machine for more than 20 years.

Characteristics of vacuum emulsifier

1. The material in contact with the material is made of high-quality SUS316L stainless steel, and the inner and outer surfaces of the equipment are polished with a mirror finish, leaving no dead corners and meeting GMP requirements.

2. The automatic control adopts original imported electrical accessories, commonly used brands such as Schneider, Siemens, etc.

3. The emulsification tank is equipped with a CIP cleaning system, which avoids the cumbersome traditional cleaning methods and makes the cleaning work easier and more efficient.

4. The emulsification tank adopts a triple mixing system to reduce the sealing process. Keeping the entire emulsification process in a vacuum sealed state can not only destroy the bubbles generated during material emulsification, but also prevent air from entering.

5. The homogenizer adopts advanced technology, with an emulsification speed of 0-3500r/min and a slow stirring speed of 0-65r/min. It has good homogenization effect and can achieve ideal emulsification effect within ten minutes.

vacuum emulsifier,Vacuum emulsification unit and Vacuum Emulsifying Mixer for Pharmaceutical, Cosmetic, and Chemical

A Vacuum Emulsifying Mixer is a specialized piece of equipment used extensively in the pharmaceutical, cosmetic, and chemical industries for creating high-quality emulsions, dispersions, and suspensions.

Key Components:

- Vacuum System: Removes air and gases from the mixing chamber to prevent oxidation and contamination, resulting in a finer, more stable product.

- Emulsifying Head (Homogenizer): High-shear mixer that breaks down particles and droplets to create a uniform mixture.

- Mixing Tank: The main container where materials are combined and processed.

- Agitator: Ensures thorough mixing and blending of ingredients.

- Heating/Cooling Jacket: Controls the temperature of the mixture, which is crucial for many formulations.

- Control Panel: Allows operators to monitor and adjust parameters such as speed, temperature, and vacuum pressure.

Applications:

Pharmaceutical Industry:

Creams and Ointments: Produces smooth, homogeneous medicinal creams and ointments with consistent texture and stability.

Lotions and Gels: Ensures the even distribution of active pharmaceutical ingredients.

Cosmetic Industry:

Skincare Products: Creates stable emulsions for products like moisturizers, sunscreens, and anti-aging creams.

Haircare Products: Used for producing shampoos, conditioners, and styling gels.

Chemical Industry:

Adhesives and Sealants: Mixes compounds to achieve desired adhesive properties.

Paints and Coatings: Ensures uniform pigment dispersion and consistency.

Benefits:

- High Efficiency: Rapidly produces fine emulsions and dispersions, reducing production time.

- Consistent Quality: Ensures uniformity and repeatability in product batches.

- Enhanced Stability: Vacuum mixing reduces the risk of contamination and oxidation, leading to longer shelf life.

- Versatility: Capable of handling a wide range of viscosities and material types.

- Scalability: Available in various sizes, from laboratory-scale mixers to large industrial units.

Operating Principles:

- Vacuum Creation: Before mixing begins, the vacuum system removes air from the tank. This minimizes air bubbles and potential contamination.

- Ingredient Loading: Raw materials are introduced into the mixing tank.

- Emulsification and Homogenization: The high-shear emulsifying head breaks down particles and droplets, creating a fine, uniform mixture.

- Mixing and Agitation: The agitator ensures all ingredients are thoroughly blended.

- Temperature Control: The heating/cooling jacket maintains the desired temperature throughout the process.

- Final Product Discharge: Once the mixing is complete, the final product can be discharged for further processing or packaging.

Maintenance and Safety:

- Regular cleaning and sterilization are essential, especially in pharmaceutical and cosmetic applications, to prevent contamination.

- Routine maintenance of mechanical parts, such as seals and bearings, ensures long-term reliability.

- Operators should be trained in the safe use of the equipment, including proper handling of vacuum systems and high-shear mixers.

Vacuum Emulsifying Mixer

This unit can be used for production of ointments and creams in cosmetic and pharmaceutical factories, especially for the preparation and emulsification of ground substance with large viscosity and high content of solid.

Features:

This unit has such features as simple operation, stable performance, good homogenization, high production efficiency, convenient cleaning, reasonable structure, small floor space, and high automatization etc.

| SN | Specification: | ZJR-1000 |

| 1 | whole volume of container | 1200L |

| 2 | Service volume of container | 1000L |

| 3 | Min. output | 300L |

| 4 | Machine size | 3800/3870/3150-4550 |

| 5 | Weight | 4200kg |

| 6 | Heating | Electric/steam |

| 7 | slow-speed mixing system | 0-40r/min; 3.7kw |

| 8 | high-speed homogenizing | 0-3500r/min; 15kw |

| 9 | power of vacuum pump | 4kw |

| 10 | Main installation power | 29kw |

| SN | Specification: | ZRJ-500 |

| 1 | whole volume of container | 650L |

| 2 | Service volume of container | 500L |

| 3 | Min. output | 200L |

| 4 | Machine size | 2800/3600/2700-3950 |

| 5 | Weight | 3500kg |

| 6 | Heating | Electric/steam |

| 7 | slow-speed mixing system | 0-40r/min; 2.2kw |

| 8 | high-speed homogenizing | 0-3500r/min; 7.5kw |

| 9 | power of vacuum pump | 3.85kw |

| 10 | Main installation power | 19kw |

| SN | Specification: | ZRJ-350 |

| 1 | whole volume of container | 500L |

| 2 | Service volume of container | 350L |

| 3 | Min. output | 150L |

| 4 | Machine size | 2650/3240/2560-3600 |

| 5 | Weight | 2800kg |

| 6 | Heating | Electric/steam |

| 7 | slow-speed mixing system | 0-40r/min; 2.2kw |

| 8 | high-speed homogenizing | 0-3500r/min; 7.5kw |

| 9 | power of vacuum pump | 2.35kw |

| 10 | Main installation power | 15.75kw |

| N | Specification: | ZRJ-100 |

| 1 | whole volume of container | 150L |

| 2 | Service volume of container | 100L |

| 3 | Min. output | 60L |

| 4 | Machine size | 2920/2120/2200-3000 |

| 5 | Weight | 1900kg |

| 6 | Heating | Electric/steam |

| 7 | slow-speed mixing system | 0-40r/min; 1.5kw |

| 8 | high-speed homogenizing | 0-3500r/min; 4kw |

| 9 | power of vacuum pump | 1.45kw |

| 10 | Main installation power | 11kw |

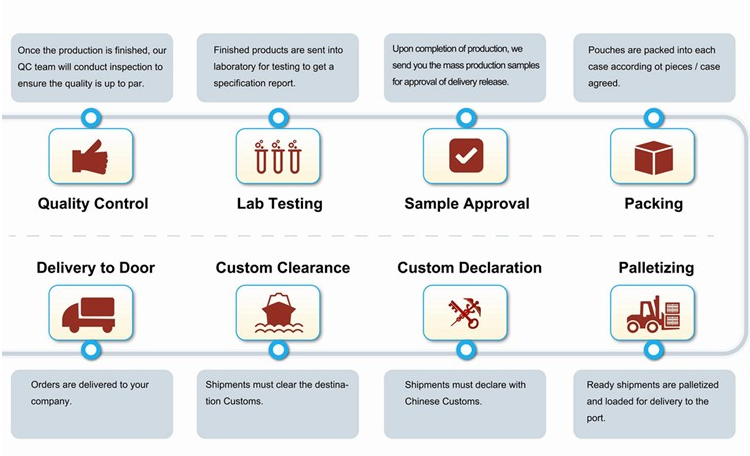

1.Nomally shipping steps:

2.Our packing and shipping:

Pre-Sales Service:

* Inquiry and consulting support.

*Quickly reaction.

*Factory inspection available anytime.

After-Sales Service:

*Prompt technical support

*Engineers available to service machinery overseas

*Installation &commissioning,good training for customers.

Q1.What's your delivery method?

A1:We commonly use sea transportation, using container to deliver the goods through Shanghai Port.

Q2.What products can you provide?

A2:Our main product includes powder mixers,granulating equipments,drying equipments,capsule fillers,blister packing machines,tablet/capsule counting filling line,ampoule/vial/oral liquid filling line includes ultrasonic washing machine,sterilization oven,filling capping machine,labeling machine.

Q3. What's the payment terms?

A3:We will confirm the payment with you when quoting, like FCA, CIF or others.T/T is the main payment.

Q4.How do you ensure your product quality?

A4:We conduct inspections in every production procedure, and for finished products, we will take 100% inspection depend on international standards according to customer's requirements.

Q5:Does the machine power voltage meet buyers' factory power source?

A5: We can do it as your request.

Q6: Is it difficult to install the machine ?

A6: For standard small machines, the machines will be packed with no take apart, it comes to you to be a complete machine; you just need to connect power and compressed air to machine, then begin to operate the machine.

For large size machines, we will take the machine apart, on condition that we do our best to keep the machine easy to assembly.

You will get videos and instructions about installation of machine from us.

SUPM is a national high-tech enterprise integrating R&D, production, sales and related services of pharmaceuticals, food, cosmetics industries.

![(4[KDGL_NF%E6%2]D`4JYP](http://img.yfisher.com/m5591/171695525954e613.png)

![0OC}YRDYXP])TO]QMXZ48IJ](http://img.yfisher.com/m5591/171695526340fe25.png)

![KE1PX$_SO]LLORZU3`DH8UW](http://img.yfisher.com/m5591/1716955263299568.png)

![RX2]L7{%NOW0`YXF9~)M{_G](http://img.yfisher.com/m5591/171695526519cd71.png)