High Efficiency Vertical Milk Homogenizer

High pressure homogenizers are mainly used in industries such as biology, medicine, food, and chemical engineering for cell lysis, beverage homogenization, and fine chemical processing. They are used to prepare products such as liposomes, fat emulsions, nanosuspensions, microemulsions, lipid microspheres, emulsions, dairy products, infusion solutions, dyes, solar panel coatings, and conductive coatings. The international market size of this field exceeds 10 billion yuan. Among them, the production of pharmaceutical emulsions must use ultra-high pressure homogenizers (with a pressure of at least 20000 psi), and the high-pressure homogenizers used in the domestic pharmaceutical industry are almost entirely dependent on imports.

principle

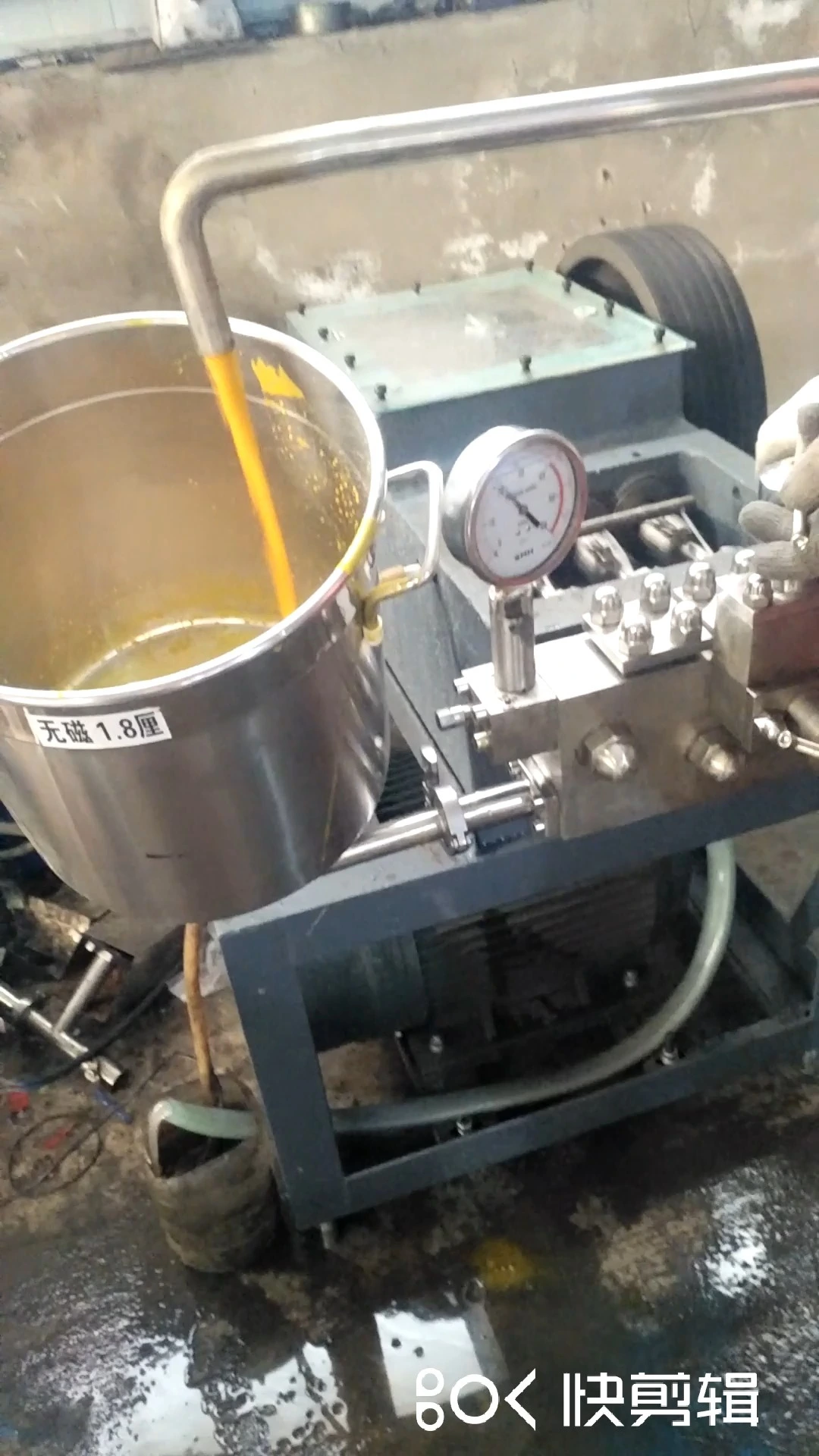

The high-pressure homogenizer is mainly composed of a high-pressure homogenization chamber and a pressurization mechanism. The interior of the high-pressure homogenization chamber has a specially designed geometric shape. Under the action of the pressurization mechanism, the high-pressure solution quickly passes through the homogenization chamber, and the material is simultaneously subjected to mechanical forces such as high-speed shear, high-frequency oscillation, cavitation phenomenon, and convective impact, as well as corresponding thermal effects. The resulting mechanical forces and chemical effects can induce changes in the physical, chemical, and structural properties of the material's macromolecules, ultimately achieving homogenization.

Therefore, the high-pressure homogenization chamber is the core component of the equipment, and its unique geometric structure inside is the main factor determining the homogenization effect. The pressurization mechanism provides the required pressure for fluid materials to pass through the homogenization chamber at high speed, and the pressure level and stability will also affect the quality of the product to a certain extent.

Product Description:

Industrial Machinery:

It is suitable for the homogenizing of liquid products whose viscosity is lower than 0.2Pa and whose temperature is lower than 80 C such as dairy, beverage, makeup, and medicine and so on. This equipment transports the processed material to homogenizing vale in high pressure way by triple plunger pump, making the material receive complex force such as turbulence, cavity, cut when the material flow past the little space between the valve plate and the valve seat to reach the purpose of emulsification and homogenizing.

Structure of Homogenizer:

The stator works in concert with rotor, the working head (the stator and rotor forging manufacturing) is claw type structure, double suction and the shear efficiency is high.

Usages of Homogenizer:

Application in biological medicine; Food industry; Day care; Coating printing ink; Nano-materials; Petroleum chemical; Printing and dyeing auxiliaries; Paper industry; Pesticide and fertilizer; Plastic rubber; Power electronics and other fine chemical industry.

Characteristics of Homogenizer:

1. With high stability, low noise, easy clean, flexible advantages. It can be widely used in industrial production of emulsion, uniform and scattered.

2. Making the material refined mix under the triple action of crowding inquiry, strong impact and loss-pressure expansion.

3. For soybean milk and other kinds of dairy drink milk, under high pressure for homogeneous

4. It can improve the degree of fineness and loose, making its inherent quality obviously improved.

5. It can prevent or reduce material liquid to layered, improve the look of the material liquid effect, making its color brighter, fragrance thicker, tastes well.

| Model | Flow (L/H) | Max . Pressure (M P a) | Working Pressure (MPa) | Weight (kg) | Outer Size (cm) | Power (Kw) |

| GYB 30-40 | 30 | 40 | 0~32 | 230 | 95×75×120 | 2.2 |

| GYB 500-25 | 500 | 25 | 0~20 | 670 | 100×75×110 | 5.5 |

| GYB 1000-25 | 1000 | 25 | 0~20 | 700 | 100×75×110 | 7.5 |

| GYB 1500-25 | 1500 | 25 | 0~20 | 720 | 100×75×110 | 11 |

| GYB 1000-30 | 1000 | 30 | 0~24 | 720 | 100×75×110 | 11 |

| GYB 300-40 | 300 | 40 | 0~32 | 670 | 100×75×110 | 5.5 |

| GYB 500-40 | 500 | 40 | 0~32 | 670 | 100×75×110 | 7.5 |

| GYB 300-60 | 500 | 60 | 0~48 | 720 | 100×75×110 | 11 |

| GYB 500-60 | 300 | 60 | 0~48 | 700 | 100×75×110 | 7.5 |

| GYB 300-100 | 500 | 70 | 0~56 | 720 | 100×75×110 | 11 |

| GYB 5000-20 | 5000 | 20 | 0~16 | 1500 | 130×125×150 | 37 |

| GYB 2000-25 | 2000 | 25 | 0~20 | 1150 | 120×105×140 | 15/18.5 |

| GYB 2500-25 | 2500 | 25 | 0~20 | 1250 | 130×106×145 | 22 |

| GYB 3000-25 | 3000 | 25 | 0~20 | 1350 | 130×110×145 | 22/30 |

| GYB 4000-25 | 4000 | 25 | 0~20 | 1400 | 130×125×150 | 37 |

| GYB 2000-30 | 2000 | 30 | 0~24 | 1350 | 130×125×145 | 22 |

| GYB 1000-40 | 1000 | 40 | 0~32 | 1200 | 120×105×140 | 15 |

| GYB 1500-40 | 1500 | 40 | 0~32 | 1350 | 130×120×145 | 22 |

| GYB 2000-40 | 2000 | 40 | 0~32 | 1400 | 130×120×145 | 30 |

| GYB 2500-40 | 2500 | 40 | 0~32 | 1500 | 130×125×150 | 37 |

| GYB 1000-60 | 1000 | 60 | 0~48 | 1350 | 130×120×145 | 22 |

| GYB 1500-60 | 1500 | 60 | 0~48 | 1500 | 130×125×150 | 30 |

| GYB 1000-80 | 1000 | 80 | 0~64 | 1500 | 130×125×150 | 30 |

| GYB 5000-25 | 5000 | 25 | 0~20 | 2000 | 210×110×105 | 45 |

| GYB 6000-25 | 6000 | 25 | 0~20 | 2450 | 250×130×110 | 55 |

| GYB 7000-25 | 7000 | 25 | 0~20 | 2550 | 250×130×110 | 65 |

| GYB 5000-30 | 5000 | 30 | 0~24 | 2000 | 210×110×105 | 45 |

| GYB 6000-30 | 6000 | 30 | 0~24 | 2500 | 250×130×110 | 55 |

| GYB 4000-32 | 4000 | 32 | 0~25.6 | 2000 | 210×110×105 | 45 |

| GYB 3000-40 | 3000 | 40 | 0~32 | 2000 | 210×110×105 | 45 |

| GYB 4000-40 | 4000 | 40 | 0~32 | 2500 | 250×130×110 | 55 |

| GYB 5000-40 | 5000 | 40 | 0~32 | 2600 | 250×130×110 | 65 |

| GYB 2000-60 | 2000 | 60 | 0~48 | 2000 | 210×110×105 | 45 |

| GYB 3000-60 | 3000 | 60 | 0~48 | 2850 | 250×130×110 | 65 |

| GYB 2000-70 | 2000 | 70 | 0~56 | 2000 | 210×110×105 | 45 |

| GYB 1500-80 | 1500 | 80 | 0~64 | 2000 | 210×110×105 | 45 |

| GYB 8000-20 | 8000 | 20 | 0~16 | 2550 | 250×130×110 | 65 |

| GYB 1000-100 | 1000 | 100 | 0~80 | 2000 | 210×110×105 | 37 |

| GYB 10000-25 | 10000 | 25 | 0~20 | 3500 | 215×200×110 | 90 |

| GYB 1200-100 | 1200 | 100 | 0~85 | 2000 | 210×110×105 | 45 |

| GYB 1600-100 | 1600 | 100 | 0~85 | 2600 | 250×130×110 | 55 |

| GYB 2500-100 | 2500 | 100 | 0~85 | 3800 | 2100×200×110 | 90 |

2.Our packing and shipping:

Pre-Sales Service:

* Inquiry and consulting support.

*Quickly reaction.

*Factory inspection available anytime.

After-Sales Service:

*Prompt technical support

*Engineers available to service machinery overseas

*Installation &commissioning,good training for customers.

Q1.What's your delivery method?

A1:We commonly use sea transportation, using container to deliver the goods through Shanghai Port.

Q2.What products can you provide?

A2:Our main product includes powder mixers,granulating equipments,drying equipments,capsule fillers,blister packing machines,tablet/capsule counting filling line,ampoule/vial/oral liquid filling line includes ultrasonic washing machine,sterilization oven,filling capping machine,labeling machine.

Q3. What's the payment terms?

A3:We will confirm the payment with you when quoting, like FCA, CIF or others.T/T is the main payment.

Q4.How do you ensure your product quality?

A4:We conduct inspections in every production procedure, and for finished products, we will take 100% inspection depend on international standards according to customer's requirements.

Q5:Does the machine power voltage meet buyers' factory power source?

A5: We can do it as your request.

Q6: Is it difficult to install the machine ?

A6: For standard small machines, the machines will be packed with no take apart, it comes to you to be a complete machine; you just need to connect power and compressed air to machine, then begin to operate the machine.

For large size machines, we will take the machine apart, on condition that we do our best to keep the machine easy to assembly.

You will get videos and instructions about installation of machine from us.

SUPM is a national high-tech enterprise integrating R&D, production, sales and related services of pharmaceuticals, food, cosmetics industries.

![(4[KDGL_NF%E6%2]D`4JYP](http://img.yfisher.com/m5591/171695525954e613.png)

![0OC}YRDYXP])TO]QMXZ48IJ](http://img.yfisher.com/m5591/171695526340fe25.png)

![KE1PX$_SO]LLORZU3`DH8UW](http://img.yfisher.com/m5591/1716955263299568.png)

![RX2]L7{%NOW0`YXF9~)M{_G](http://img.yfisher.com/m5591/171695526519cd71.png)