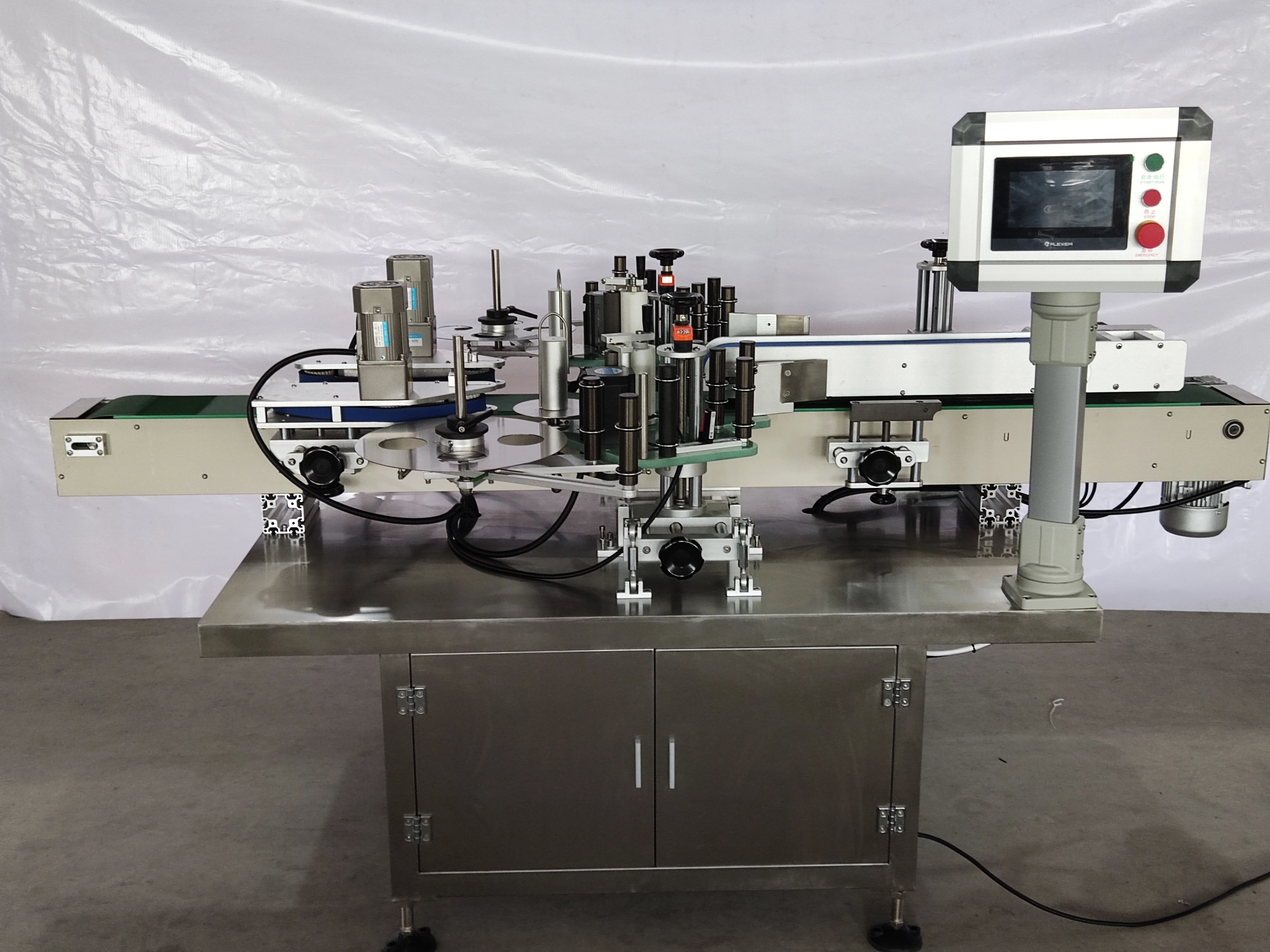

UN-3520 Automatic High-speed Diagonal Labeling Machine

Features

Four working methods: upper surface sealing and labeling, lower surface sealing and labeling, and two diagonal sealing and labeling.

The pressing device ensures the stability of the box body and the labeling accuracy during labeling, and is especially suitable for light and small boxes.

Optional missing sticker automatic detection and removal function.

Printing equipment: It can flexibly choose inkjet printer or coding machine to complete the coding at the same time as labeling.

Reserve the input / output signals and interfaces. It can accept the control signal of the upper computer in the online state. It can be used in conjunction with the production line for easy management.

Optional transparent protective cover, equipped with safety lock switch, to ensure the safety of operators.

Bottle sorter and conveyor belt are driven by individually adjustable motors.

Two support methods can be flexibly selected according to different products.

UN-3520 Automatic High-speed Diagonal Labeling Machine

Device function:

1. It can stick single-angle and diagonal labeling of flat boxes and square boxes of different specifications.

2. Synchronous chain proofreading mechanism ensures smooth and accurate proofreading.

3. Screw engraving control structure, accurate labeling. The adjustment range is large. Can adapt to boxes of various sizes.

4. The transparent label will not blister and the label will not wrinkle.

technical parameter

Voltage specification | AC220V 50/60HZ Dual Phase |

power consumption | 4KW |

Labeling speed | 0-220 boxes/min (depending on the label length) |

Labeling accuracy | Plus or minus 1mm (except the box and the label itself error) |

Applicable container range | 260*80*76mm (maximum size) |

Applicable label range | Diameter (round label) not more than 50mm |

largest label supply | Diameter 350mm, inner diameter of paper roll 76mm The distance between the upper and lower edges of the label and the upper and lower edges of the backing paper is 2mm |

Dimensions | 2400*1350*1500mm |

Self-adhesive label parameters:

bottom paper | 62 grams of white glassine backing paper should be selected. The paper is dense and has good internal strength and light transmittance. It is firm and not easy to be torn. Die cutting performance is excellent |

basic gram weight | 62g/㎡±5% Thickness: 55μm±5% |

Tensile resistance | Machine direction: 16kg/25mm Lateral: 7kg/25mm |

tear resistance | Machine direction: 25g/sheet Horizontal: 31g/sheet |

Transparency | 52% Label pitch: 3mm±0.15mm The distance between the upper and lower edges of the label and the upper and lower edges of the backing paper: 2mm |

work process

Single row horizontal feeding--distribution--conveying--synchronized top belt clamping--2 labels are attached to the upper/lower positions on both sides (half upright and suspended)--double-sided labeling-- Touch the mark on both sides to the top/bottom corners--Single row horizontally lying position discharge

The boxes are arranged horizontally. Before labeling, the separation wheel separates the required distance for labeling and stroking, and then it is clamped by the main conveyor belt and the synchronous top belt. When reaching the labeling station, trigger the measuring object electric eye and trigger the labeling head to apply the label to the end face (side) of the box. Then, under the clamping operation of the top belt and the main conveyor belt, the two labels are respectively suspended through the buckle angle. Crutch to the top and bottom of the box. It can realize the double-sided diagonal sealing and pasting of the box.

The whole machine is controlled by PLC, and the Chinese interface touch screen operation interface. All electric control parameters, operating parameters, status and count can be set on the touch screen and more than 50 groups of recipes can be stored on the right, and the recipe parameters can be directly called.

When changing labels of different lengths, there is no need to adjust the position of the label sensor, just set or call the corresponding stop label position on the touch screen.

SUPM is a national high-tech enterprise integrating R&D, production, sales and related services of pharmaceuticals, food, cosmetics industries.