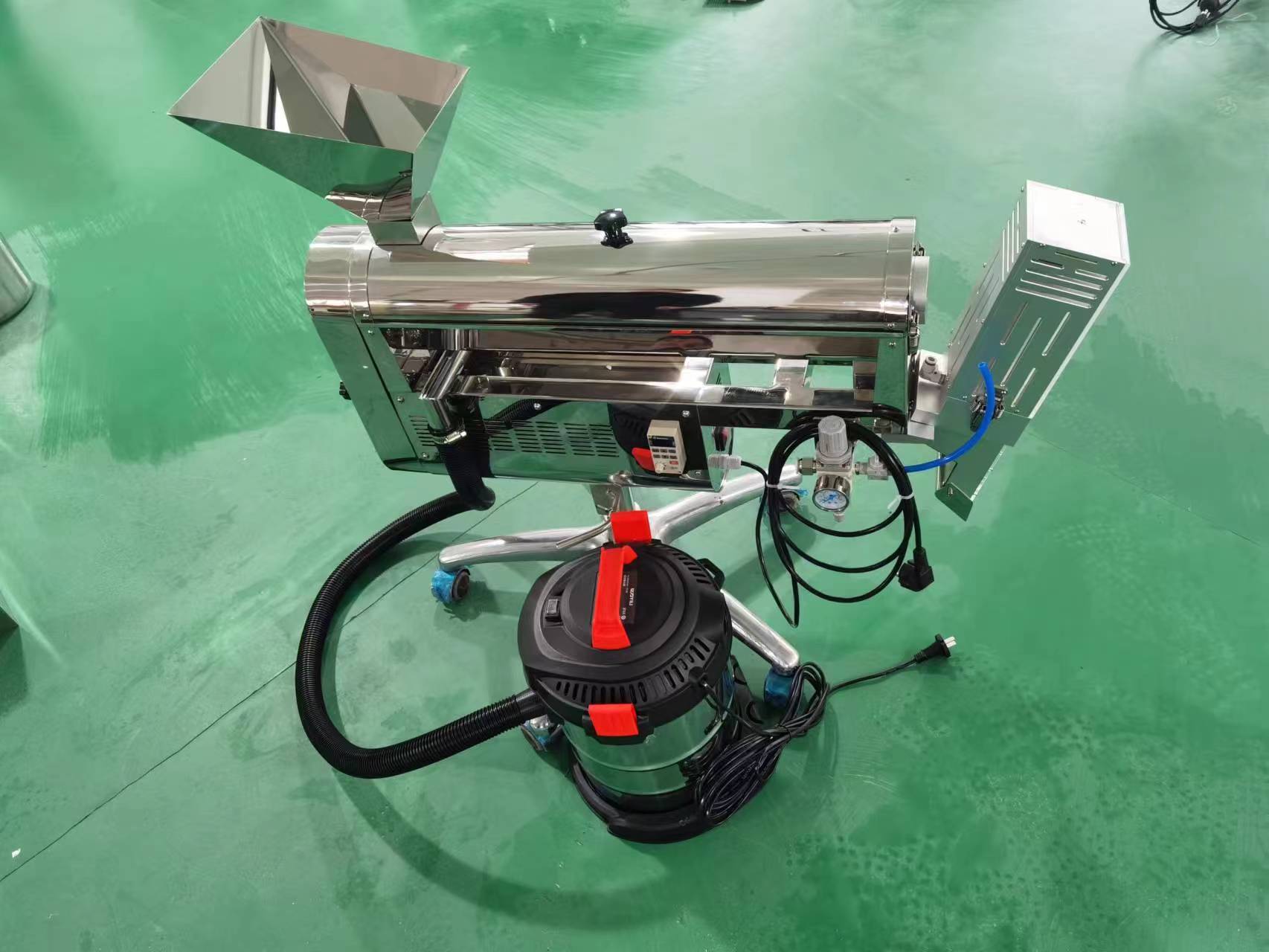

It is special equipment for pharmaceuticals.

It has the function of polishing and cleaning the dust on capsules in order to improve their fineness and meet the hygiene standard of pharmaceutical trade

It is suitable for polishing any capsules.

It is usually used togther with semi-automatic or automatic capsule filler.

All made of stainless steel 304

production efficiency | 150000capsules/min. |

Power | 220V,50HZ,1PH |

Weight | 40kg |

Total Power | 0.18KW |

Vacuum dust-intake | 2.7M3/min-0.01MPa |

Compressed Air | 0.25M3/min-0.3MPa |

Overall Dimensions | 1115*400*930mm(L*W*H) |

The performance of machine is greatly excellent, the whole machine adopts stainless steel to be made, the selecting brush adopts fullering connection with fast speed, convenience of dismantling, cleaning thoroughly, the rotation speed of motor is controlled by converter, it can bear great starting pressure with steady running, its socket is equipped with rolling device with flexible operation and high efficiency as well high purity of polishing. The defected products can be separated completely.

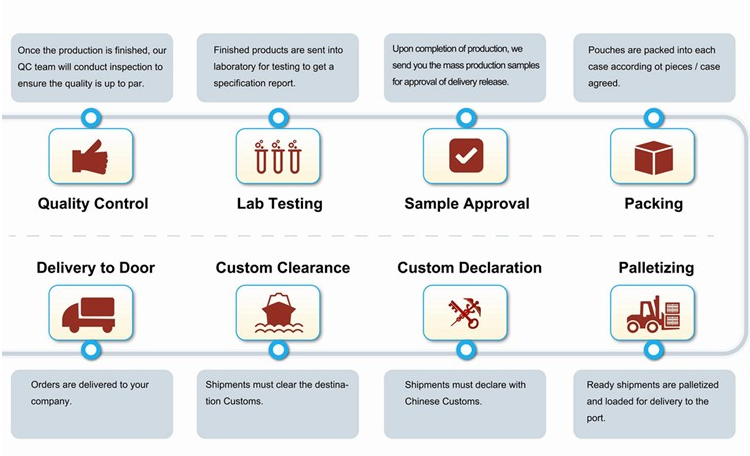

1.Nomally shipping steps:

2.Our packing and shipping:

Pre-Sales Service:

* Inquiry and consulting support.

*Quickly reaction.

*Factory inspection available anytime.

After-Sales Service:

*Prompt technical support

*Engineers available to service machinery overseas

*Installation &commissioning,good training for customers.

Q1.What's your delivery method?

A1:We commonly use sea transportation, using container to deliver the goods through Shanghai Port.

Q2.What products can you provide?

A2:Our main product includes powder mixers,granulating equipments,drying equipments,capsule fillers,blister packing machines,tablet/capsule counting filling line,ampoule/vial/oral liquid filling line includes ultrasonic washing machine,sterilization oven,filling capping machine,labeling machine.

Q3. What’s the payment terms?

A3:We will confirm the payment with you when quoting, like FCA, CIF or others.T/T is the main payment, and D/P is acceptable as well.

Q4.How do you ensure your product quality?

A4:We conduct inspections in every production procedure, and for finished products, we will take 100% inspection depend on international standards according to customer's requirements.

Q5:Does the machine power voltage meet buyers' factory power source?

A5: We can do it as your request.

Q6: Is it difficult to install the machine ?

A6: For standard small machines, the machines will be packed with no take apart, it comes to you to be a complete machine; you just need to connect power and compressed air to machine, then begin to operate the machine.

For large size machines, we will take the machine apart, on condition that we do our best to keep the machine easy to assembly.

You will get videos and instructions about installation of machine from us.

![(4[KDGL_NF%E6%2]D`4JYP](http://img.yfisher.com/m5591/171695525954e613.png)

![0OC}YRDYXP])TO]QMXZ48IJ](http://img.yfisher.com/m5591/171695526340fe25.png)

![KE1PX$_SO]LLORZU3`DH8UW](http://img.yfisher.com/m5591/1716955263299568.png)

![RX2]L7{%NOW0`YXF9~)M{_G](http://img.yfisher.com/m5591/171695526519cd71.png)