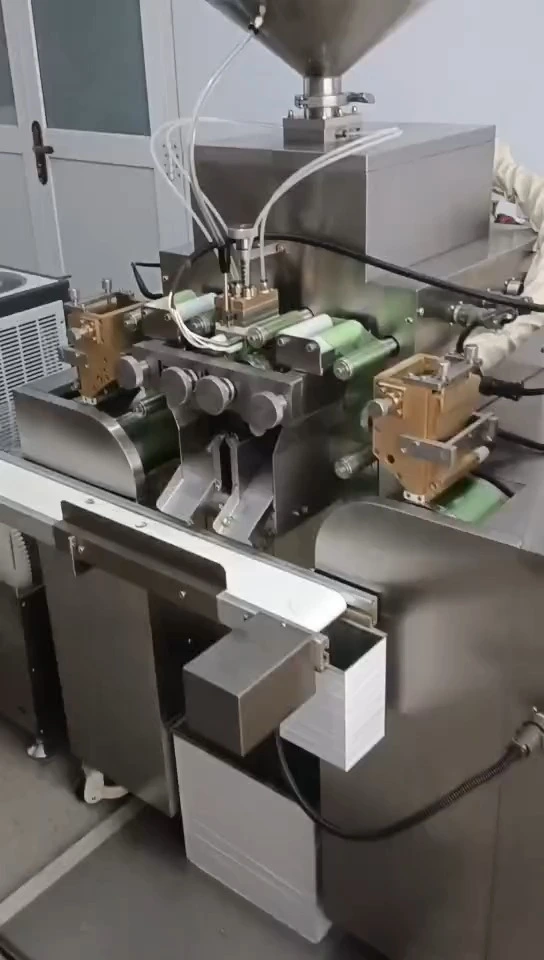

Softgel production line

Features of the equipment

The whole machine adopts an intelligent PLC control system, which works stably and reliably, and is easy to operate.

The mold, rubber wheel, and mesh shaft of the equipment host are adjusted separately, effectively solving the problem of accumulation of capsule rubber in the production of different products, making the operation more convenient and efficient.

The feed pump uses a newly designed cam drive, with a loading accuracy error of ≤ 1.5%, avoiding the wear caused by the traditional crankshaft running for a long time, resulting in inaccurate loading, and extending the service life of the components.

The latest optimized design of the mold ensures product quality while increasing output, while also improving the utilization rate of the mesh adhesive, saving costs, and achieving greater output.

The mold alignment adopts a precision adjustment rod device to achieve front alignment and precision adjustment, and the operation is convenient. It can achieve single person alignment operation and avoid mold running.

The gelatin box adopts automatic control of the glue solution to reduce the difficulty of manual operation. The contact area with the rubber wheel adopts a new PTFE soft contact method, effectively avoiding wear and tear caused by equipment operation, ensuring the flatness and cross contamination of the rubber, and providing better assurance for producing high-quality capsules.

The rubber lubrication adopts precise electromagnetic pump control method and can adjust the lubricating oil amount online, achieving ultra micro lubrication and saving a lot of cost and time for rapid drying of capsules in the later stage.

The rubber wheel is made of precision machined 304 stainless steel material, suitable for both water and air cooling, with clean water as the medium and low cost. The automatic control of the water cooler is stable and reliable, and can achieve 24-hour uninterrupted continuous production.

The conveyor is designed to be lightweight, with a smooth PTFE coated TR fiber belt that is non-toxic, non stick, easy to disassemble and wash, while avoiding the accumulation of finished capsules.

The dryer is made of all stainless steel material with a unique structural design, which ensures that the finished capsules are evenly dried and shaped to avoid adhesion. The rotating cage adopts oil-free lubrication transmission, and the bottom is equipped with an oil receiving tray, which is clean and hygienic during operation.

The entire equipment is made of high-quality materials, and all bearings are imported from Japan and Germany, ensuring the accuracy and service life of the equipment The entire equipment has a power of 3KW, 220V, low energy consumption, and a small footprint (4 square meters)

(1)Main machine (pill making system)

The host adopts a computer control system and PLC touch screen operation

Production capacity: 1000-8000 capsules/hour (calculated based on 500mg olive type)

Roll mold size: Φ 64mm

Rolling die speed: 0-5rpm continuously variable speed

Fluid single column plug supply: 0-1.2ml (customized for large quantities)

Finished capsule loading accuracy: ± 1.5%

Equipment power: 2kW

Power supply system: 1P AC220V 50-60Hz

Size: 900X700X1600mm

Weight: 450kg

(2) Drying machine (shaping system)

Drying cage size: φ 350x480mm

Drying cage speed: 22rpm

Equipment power: 0.45kW

Fan power: AC220V 50HZ 50W

Size: 800X500X850mm

Weight: 50kg

SUPM is a national high-tech enterprise integrating R&D, production, sales and related services of pharmaceuticals, food, cosmetics industries.